Updated 4/10/2023: This article was originally written by a guy who helped build DISTO into the world-leader in laser distance meters in the 90's. Hugh retired, but his advice is as relevant as it ever was except for a warning about cheap sonic measuring tools. We don't see those so much these days, but we do see a lot of gray-market tools being sold in the US, so we updated that section.

I’ve done a ton of renovation work on a house that was built in the 1880s. Every square inch has been rebuilt with a cellar full of power tools that I use almost every weekend. And I remember the day it occurred to me how many cheap, broken tools I've tossed.

I’m an engineer. As much as I hate to perpetuate the stereotype, I normally don't part with a buck unless I’ve done my homework and, in this case, it was obvious that the dog ate my homework.

Now I spend the extra couple of bucks to buy a tool that will last.

I’ve been working in measurement technology for almost 25 years, and 12 of those have been with Laser Distance Meters (or Laser Distance Measurers), also known as LDMs. As far as LDMs go, from my perspective, you should ask yourself the following questions as you narrow down your choices:

-

Do you measure outside?

If you work outside, an optical scope or digital point finder is a must.

Without a scope or a point finder, you can see a laser point at a maximum distance of about 30 feet on a bright day. Chances are, if you are measuring outside, 30 feet isn’t going to cut it.

A sighting scope – similar to a range finder on an old fixed lens camera – was the technology we first used to solve the outdoor use problem as far back as the first DISTO, and there are still LDMs with optical scopes on the market today.

Leica Geosystems now uses 4x zoom digital point finder technology similar to the zoom function on a digital camera. The crosshairs on the LCD display are precisely calibrated with the laser, so you know that, whether you can see the laser or not, you are measuring to the point you want when you put that point in the crosshairs.

-

Are you using design software?

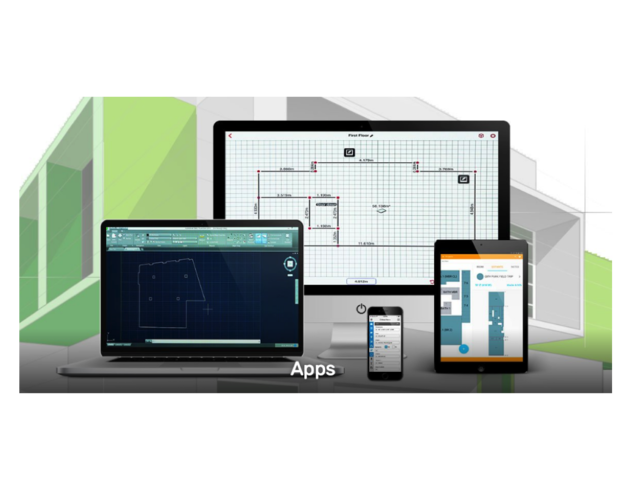

Bluetooth®-enabled LDMs transmit precise measurements to these apps in real time, as you take them. We hear from interior designers, Building Information Modelers, and design architects who tell us that this technology has cut the time it takes to build an accurate floor plan in half.

Yes, sometimes Bluetooth® LDMs are the more expensive, top-of-the-line models. But what is your time worth? If you cut your measuring time in half when getting accurate measurements the first time, how long would it take before you are in the black on a $500 or $800 investment? With new entry-level LDMs, you can get an LDM with Bluetooth® for under $150. Bluetooth® is a "must-have" for me.

-

Are you replacing another measuring tool with an LDM?

If you use a measuring wheel or a long tape, think about the measurements that take the most time or are the most difficult to get. Then, select a measuring tool that solves the problems you struggle with the most.

For example, on many active construction sites, it can be difficult to get a level horizontal distance from point A to point B simply because materials are stacked up against the wall or people and machinery are in the way.

An LDM with a tilt sensor measures the angle and distance of the shot to subtract down to the level horizontal distance to your target. That means you can shoot over pallets, people, furniture, or whatever else is in the way and still get the measurement you need.

That’s a lot easier, and a lot safer, than climbing over stuff with a tape measure in your hand.

-

How much time do you spend measuring every week?

This is all about return on investment: How much time do you spend walking around dragging a tape or a ladder to take a measurement?

What if you didn’t have to do that anymore and you got more accurate measurements? How would you better use that time?

-

Beware of gray-market imports.

You may find a good deal for a DISTO on Amazon or eBay in the US or CA, but if its too good to be true, it probably is.

DISTOs intended for the Asian market are set to Metric units and may not be switchable to Imperial units. There is a whole history behind this, but the simple version is that this is a butterfly effect from a post WWII Japanese law that makes it illegal to sell any Imperial-unit measurement device in Japan.

(The irony is that the intent of the law was to modernize the Japanese economy after the war and it was enforced by the US -- which to this day has not adopted the metric system itself.

-

What accuracy do you need in an LDM?

Accuracy really isn’t an issue if you get a tool from a reputable company. Look for an ISO 16331-1 (International Standards Organization) certified tool.

Tools with ISO certifications cost a little more, but they cost way less than an engineered beam that is cut 1” too short thanks to a low-budget LDM.

-

What range do you need in an LDM?

Again, make sure you look for an ISO-certified tool. With ISO certifications, it's about comparing good apples to even better apples. Many things influence accuracy and range – the top two are ambient light and target color.

An ISO certified tool gives you a specification that you can count on, not one that is achievable only in perfect measurement conditions.